banner1

banner2

ADVANTAGES OF ELCTROLESS NICKEL PLATING OVER OTHER PLATING

| SR No. | ELCTROLESS NICKEL PLATING | ELCTROLYTE NICKEL CHROME/HARD CHROME |

|---|---|---|

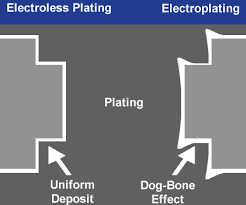

| 1 | MORE UNIFORM COATING

THICKNESS EVEN ON COMPLEX

GEOMETRIES WITH PREICISION ACCURACY OF +/- 0.001 MM. | IN CONSISTANCE DEPOSITE & HAVING COMMON PROBLEM CALLED DOGBONE EFFECT DUE TO HIGH/LOW CURRENT AREAS LEAD TO OVER UNDERPLATING OF YOUR PARTS. |

| 2 | VERY GOOD ADHESION | THIS IS PRONE TO CRACKING OR DAMAGE. |

| 3 | AS PLATED HAVING BETTER

SURFACE HARDNESS 55 TO 58

HRc, FURTHER PROPER HEAT TREATMENT IT CAN ACHIEVED UPTO 70 HRc. | MODERATE SURFACE HARDNESS AFTER ELECTROLYTIC PLATING. |

| 4 | REQUIRES NO ELECTRICITY , WHICH DECREASES THE COST | USES ELETRICITY IN PROCESS, THESE PROCESS CAN BE VERY EXPENSIVE. |

| 5 | CONSTANT COATING THICKNESS FOR HOLLOW PARTS, INTERNAL THREADS & BLIND HOLES. | DIFFICULT & UNEVEN THICKNESS FOR INTERNAL HOLLOW PARTS. |

| 6 | EXCELLENT LUBRICITY & REDUCED SURFACE SCARRING. | MODRATE LUBRICITY |

| 7 | MORE ENVIRONMENT FRIENDLY, DOES NOT REQUIRE ANY HARMFUL CHEMICAL . | IT REQUIRES HARMFUL CHEMICALS LIKE CYANIDES . |